DANOBAT RT 4000 SP Mach4Metal

Railways Railways Specialists in the supply of unique solutions for the manufacture and maintenance of rolling stock components Visit Railway Solutions Website

The DANOBAT DPL portal lathe has been specially designed and manufactured for railway

The Railways business unit of DANOBAT offers comprehensive solutions to all manufacturing processes of rolling stock parts: from the axle or the wheel, through the wheelset and to the bogie. Integral or partial solutions adapted to the customer's real needs.

Danobat

DANOBAT Arriaga kalea, 21 E-20780 ELGOIBAR SPAIN Tel.: +34 943 74 80 44 Fax: +34 943 74 31 38 [email protected] railways.danobatgroup.com COMPLETE SOLUTIONS · Consulting and development of project ideas · Accurate cycle time calculations with process simulation software · Throughput and process flow guaranteed by a plant simulation.

The DANOBAT TV1500 RW vertical lathe for wheel is specially designed for the railway industry

Danobat solutions for the machining of railway rolling stock components of all type of railway vehicles. Visit us for more information!

Danobat BM Panel Bender Automatic Sheet Metal Bending SMD Machinery

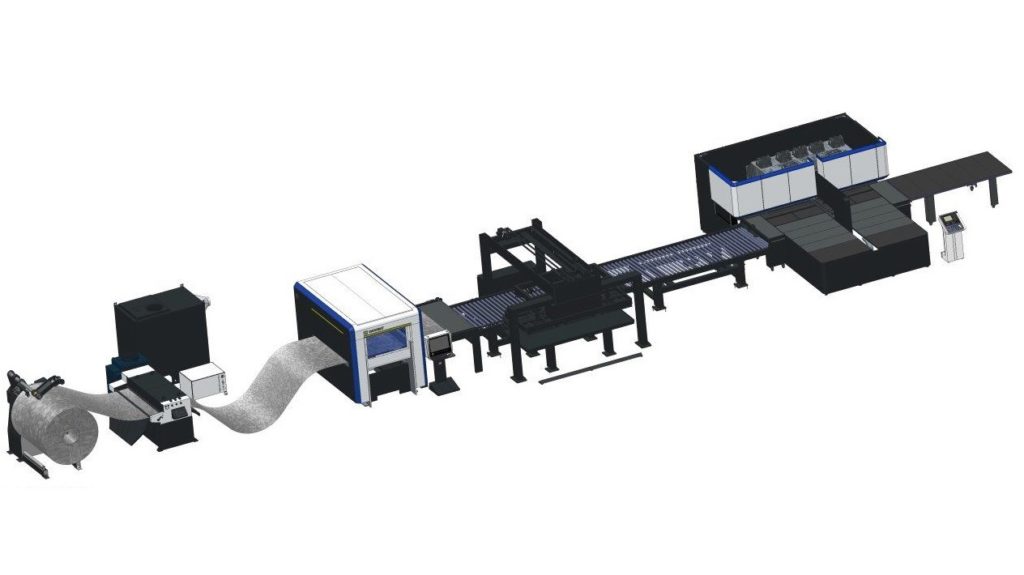

Our solution. The world's most advanced railway axle manufacturing line, both in terms of the complexity of the system, the totally integrated automation, and the variety of innovative solutions on each individual machine. Automated line for high-speed train axles which ensures the high precision and quality that these components require.

DANOBAT RT 4000 SP Mach4Metal

DANOBAT received a major order from Bergen Light Rail for the delivery of a train shunt measuring system. The Bergen Light Rail between Bergen central station and Bergen Airport comprises a 20 km double track line between Bergen city centre in the north and Bergen Airport, Flesland in the south.

The DANOBAT DRM rolling machine has been specially designed and manufactured to carry out

Designed to be installed in maintenance depots, the DANOBAT DWPM Wheel Profile Measuring System helps railway vehicle operators and maintainers by automating the wheel profile measuring process and the transfers of captured data to other systems.

Latest innovation in machining from Danobat IMTS 2016 exhibition

Home Automation solutions for Railways Looking forward to improving the efficiency of your wheel shop and reducing manual operations? Automatic transfer of wheelset, wheel, axle and bearing Automatic loading and unloading Automation of manual tasks performed by an operator Wheelset Automated guided vehicles Kick and rolls Rotary tables

The DANOBAT HG and WT high precision grinding machines have been designed for the machining of

DANOBAT 6.28K subscribers Subscribe 44 Share 6.8K views 3 years ago The world's most advanced railway axle manufacturing line, both in terms of the complexity of the system, the totally.

DANOBAT showcases its focus on industrial digitalisation and the development of advanced

Danobat, consisting of 3 renowned brands: Danobat, Overbeck and Hembrug • Danobat, based in Spain, is known for its custom-built precision grinding and machining solutions used in the.

The DANOBAT underfloor wheel lathe is a specific machine tool for the corrective maintenance of

DANOBAT's wheel profile measuring system offers a full view of the running profile of railway wheels and the ability to measure other indicators such as "Wheel thread Hollow". The unit is robust; protected and isolated from the outside with triangulation units that are designed so they do not deform, even in severe climatic conditions.

The DANOBAT DS CNC railway machining center has been specially designed and manufactured for the

Danobat Railway Systems S. Coop.. Hiru Erreka nº 6, Barrio Mekolalde, Bergara 20570, Spain Home Machines By Type By Brand For Sale with Videos Auctions Current Auctions Past Auctions Wanteds Browse Post Directory Machinery Manager Price Guide Have something to sell? About Us English English English Español Español Deutsch Français Italiano

Danobat WT Railway axle precision machining YouTube

Wheel wear is not only harmful to the rails and the railway vehicles. Many maintenance costs are also the result of a poor wheel wear management. Managing optimum wheel profiles leads to reduced costs in rolling stock maintenance. The Danobat model DWPM Wheel Profile Measuring System helps operators and maintainers by automating the diagnosis

The DANOBAT underfloor wheel lathe is a specific machine tool for the corrective maintenance of

2.1 Switch system layout. The schematic of the switch system being modelled is shown in Fig. 1.In this layout, the traditional stock rails and switch rails are replaced and redesigned as stub rails with uniform cross sections to allow for a novel actuation movement, as described by Bemment et al. [21, 22].The stub switch rails are moved in a semi-circular arc to achieve the switching motion [9.

DANOBAT RT 4000 SP Mach4Metal

[6] 2013: Danobat Railway Systems becomes part of Danobat. 2014: Start of joint venture between Danobat and the American company Marathon. 2015: Acquisition of the company Plantool OY by Danobat. 2019: Acquisition of Hembrug Machine Tools Environmental management

DANOBAT builds the world’s most advanced automated train repair shop in Australia AFM

Specifications Please contact us to enquire about specifications. Manufactured by: 1 DANOBAT allows for the easy corrective maintenance and production of railway rolling surfaces and train brake discs with their world-class lathe and borers.